South African Dust & Air Control Tvl. (Pty) Ltd

since 1951

South African Dust and Air Control Tvl. (Pty) Ltd was established in 1951 as a specialist company providing dust & air pollution control solutions. The company provides for the design manufacture and installation of equipment for the industrial mining and commercial sector. SADAC (abbreviated for South African Dust & Air Control) provides a range of standardised equipment with proven designs and construction methods, leading the industry with continuous development and technology implemented in their range. All the equipment supplied by SADAC is 100% locally manufactured in house where stringent quality controls and safety standards are kept.

Reverse Pulse Bag Filter

DUST COLLECTORS

The SADAC range of reverse pulse bag filters have been developed to cater for dust control applications where there are high dust loadings and low emissions required. This is achieved by providing a filter with a fully automatic on line cleaning capability whilst maintaining a low constant pressure drop across the filters. The SADAC reverse pulse filter design is based on an upgradeable arrangement which incorporates a modular housing and various bag lengths to suite the application.

These filters are offered with various methods of handling the collected dust particles including rotary valves, screw conveyors and auxiliary pneumatic booster systems. In addition to the standard reverse pulse filter range, SADAC offers a fully self contained reveres pulse venting filter which is predominantly used for silo venting, pneumatic conveying, and conveyor transfer point dedusting.

Fully Automatic - Reverse Pulse

Fabric dust filter unit

Low Energy Tower Scrubber

and Mechanical Shake Dust Collector

Mechanical Bag Filter

DUST COLLECTORS

The SADAC range of reverse pulse bag filters have been developed to cater for dust control applications where there are high dust loadings and low emissions required. This is achieved by providing a filter with a fully automatic on line cleaning capability whilst maintaining a low constant pressure drop across the filters.

The SADAC reverse pulse filter design is based on an upgradeable arrangement which incorporates a modular housing and various bag lengths to suite the application.

These filters are offered with various methods of handling the collected dust particles including rotary valves, screw conveyors and auxiliary pneumatic booster systems.

In addition to the standard reverse pulse filter range, SADAC offers a fully self contained reveres pulse venting filter which is predominantly used for silo venting, pneumatic conveying, and conveyor transfer point dedusting.

Scrubbers

PRIMARY DUST COLLECTORS

Sadac has developed a range of wet scrubbers suited for dust and fume control applications. The scrubber range is branded as the SADAC low energy tower. This name is derived primarily due to the principle design of maintaining a low pressure drop and a high level of filtration with a minimal water consumption. The low energy scrubber incorporates a cyclonic inlet design with a series of wet impingement sections and a final stage, moisture eliminator section.

Filters

FILTER BAGS AND CAGES

SADAC manufacturer’s supplies and installs filter bags and filter cages. These filters include tubular reverse pulse and the multi pocket types.

A wide range of bags and filter fabrics are stocked with systems in place to encode customer specifications & samples, making installations and repeat business for our customers a time saving exercise.

We manufacture filters form various materials and fabrics to cater for high temperature, moisture, static ECT

Filter Bags

Tubular - Pocket - Multi Pocket - Panel

6 x J1 16 Cyclones

Cyclones

PRIMARY DUST COLLECTORS

A comprehensive range of cyclones are available to suite most primary dust collections. These cyclones have collection efficiencies of up to 99%, and can be cost effective in applications where there are high dust loadings and coarse particles

Ducting

DUST HOODS

SADAC manufactures ducting and custom designed dust hoods to provide for a complete turn key supply

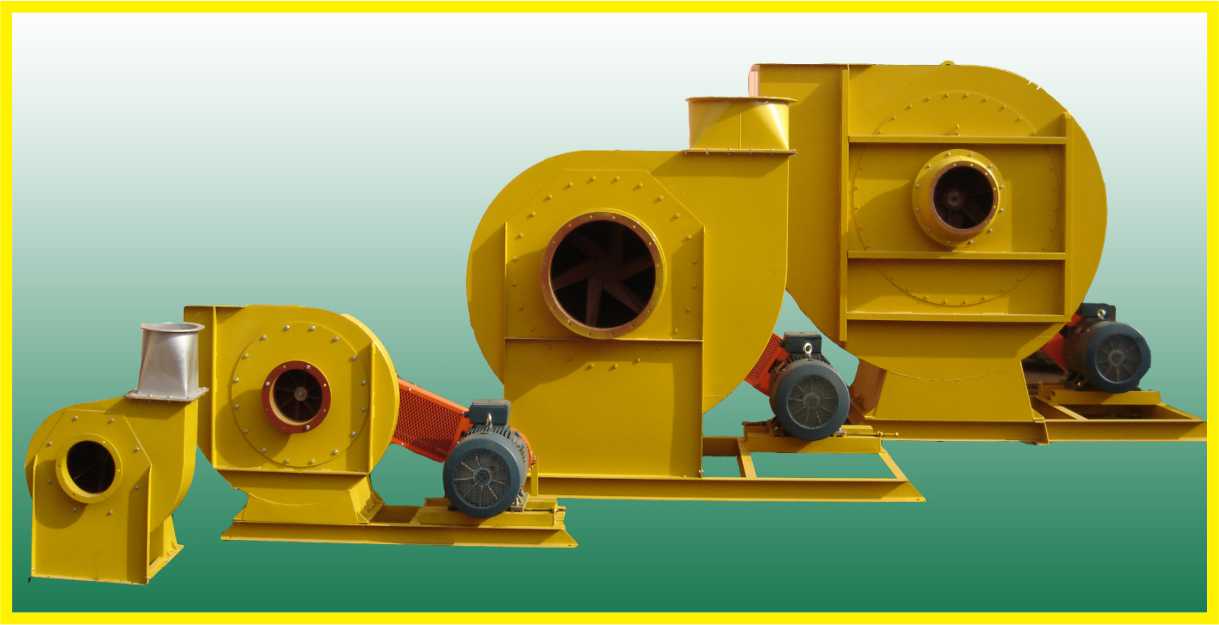

Fans

CENTRIFUGAL FANS

A comprehensive range of SADAC standard centrifugal fans are manufactured to cater for the dust and air pollution control environment.

These fans are tailored for dust collection, air filtration and paper waste handling, and are of a heavy duty construction fabricated in mild steel and stainless steel materials. The fan range comprises of radial paddle bladed, backward bladed and backward curved bladed centrifugal fans, as well as high pressure fans for pneumatic conveying and vacuum application.

P. Series Heavy Duty

CENTRUGAL FANS

Contracting

compete turn key project service

The company provides for complete turn key project services. These services entail project management, design, manufacture, delivery, installation and maintenance